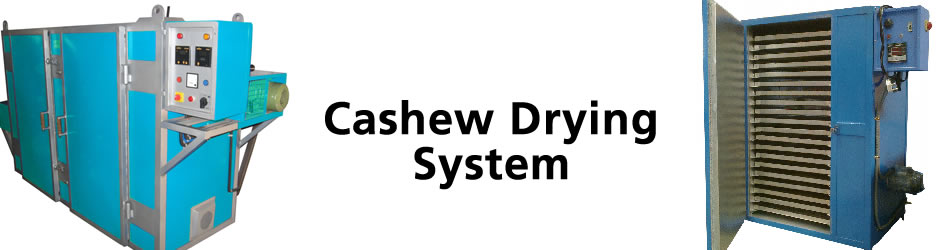

Cashew Drying System

Cashew Drying System - Borma

The shelled kernel is layered with the red skin testa. For easy removal ie to peel it has to undergo a drying process. It also removes tanning and reduces moisture content inside the kernel.. The moisture content is approximately 6% and after drying we get about 3%. During monsoons kernels will soak up the moisture very fast so drying should be higher.

It takes around 6 to 7 hours for drying, at a temperature of around 65 to 70°C. A uniform temperature is essential to avoid under drying or scorching.

MODEL |

RAJ-30BD | RAJ-60BD | RAJ-125BD | RAJ-250BD | RAJ-500BD | RAJ-1000BD |

BATCH(KG) |

30 | 60 | 125 | 250 | 500 | 1000 |

FUEL |

Wood/cashew Shell Cake/Agro Waste | |||||

DURATION |

About 6 hours at temperature of about 65° | |||||

Cashew Drying System Electric

MODEL |

RAJ-30ED | RAJ-60ED | RAJ-125ED | RAJ-250ED | RAJ-500ED | RAJ-1000ED |

BATCH(KG) |

30 | 60 | 125 | 250 | 500 | 1000 |

FUEL |

Electric | |||||

DURATION |

About 6 hours at temperature of about 65° | |||||

The shelled kernel is layered with the testa and is dried with a Cashew Dryer Machine operation.

To easily facilitate removal, i.e. to peel in order to produce the lightened kernel, the shelled kernel undergoes a drying process.

By this, the kernel is safeguarded from pest and fungus attack at this weak stage. The moisture content is approximately 6% before drying and 3% after. During monsoons, it is important that the capacity of drying should be higher than the shelling because the drying operation will be extended as the kernels will soak up the moisture very fast.

It takes around six hours for drying, at a temperature of around 70°C. A uniform temperature throughout the drier is essential to avoid under drying or scorching.

In the dried condition, the kernels must be handled with care as they are most vulnerable, being both fragile and inclined to insect infestation.